While the technical benefits of high-performance HMI are clear, a critical aspect often overlooked is user acceptance. No matter how well-designed an HMI system is, its success ultimately depends on whether operators feel comfortable using it in real-time operations. This becomes especially important in process automation, manufacturing automation, and industrial automation environments, where process control systems must function efficiently under pressure.

Contents

ToggleWhy User Acceptance Matters

The operators are the end users of the HMI, and they need to feel confident in the system to maximize its potential. If a high-performance HMI is too difficult to learn, or if operators feel that important details have been oversimplified, they might resist using it—leading to inefficiencies and even operational risks. Ensuring that operators buy into the design is key for a successful transition from traditional HMI systems to more streamlined, high-performance alternatives.

Here are a few reasons why user acceptance is vital:

- Smooth Transition: Operators may have years of experience with traditional HMIs. A well-executed transition plan—including thorough training—can ease the shift and minimize resistance.

- Confidence in Decision Making: If operators don’t trust the HMI to provide accurate and timely data, they may hesitate to rely on it during critical moments. High user acceptance ensures that operators are confident in the system’s reliability, especially for real-time monitoring in SCADA or distributed control systems (DCS) environments.

- Feedback Loop: Operators’ input is invaluable during the design and implementation phases. A feedback-driven approach can lead to customizations that enhance both usability and effectiveness, creating an HMI that meets the needs of both the system and the user.

Key Considerations for User Acceptance

To achieve strong user acceptance for high-performance HMI, the following considerations should be integrated into the design process:

1. Involve Operators Early in the Design Process

Collaborating with the operators who will use the system from the start ensures that their needs and preferences are addressed. Early engagement helps designers understand operational pain points and how the high-performance HMI can better meet them, particularly in control systems engineering and PLC programming environments. Operators are more likely to accept the new HMI if they feel their input is valued and incorporated.

2. Provide Comprehensive Training

Training is crucial in ensuring user acceptance of high-performance HMI, especially for operators familiar with traditional systems. Training should focus not just on the functionality of the new interface but also on the principles behind high-performance HMI—such as why color usage is minimal and why data is presented in certain ways. Thorough training ensures operators feel confident in interpreting the simplified visuals of a high-performance HMI, particularly in fast-paced SCADA or process automation operations.

3. Tailor the HMI to Operator Roles

In complex systems like distributed control systems (DCS) or SCADA, different operators may have varying needs. For example, a control room operator might require a different set of information than a field technician using a remote terminal unit (RTU). Customizing the HMI for different user roles ensures that everyone gets the most critical data without information overload.

Here’s an example:

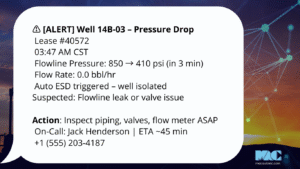

A plant supervisor and a field operator each have access to a tailored high-performance HMI. The supervisor might need a dashboard focused on overall system efficiency and key performance indicators (KPIs), while the field operator requires detailed real-time data on a specific machine. This role-based customization ensures that both users feel the system is optimized for their needs.

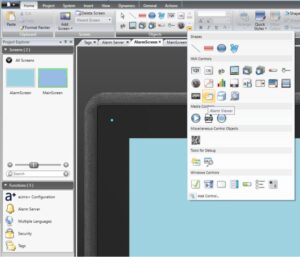

4. Conduct Usability Testing

Before rolling out the HMI system, it’s essential to test it under real-world conditions with actual operators. Usability testing in process automation or industrial automation environments can uncover potential issues early, allowing for adjustments to the design that improve user experience. Testing also familiarizes operators with the system, increasing their comfort and confidence in its usage.

Conclusion: Balancing Design with User Acceptance

In the end, high-performance HMI is as much about the user experience as it is about technical efficiency. By focusing on user acceptance—involving operators early, providing training, tailoring the system to specific roles, and conducting thorough usability tests—organizations can ensure their process control systems and industrial automation setups function optimally, leading to higher productivity and safety. At MAC Automation, we always emphasize user acceptance as a key factor when designing SCADA and HMI systems to ensure they truly meet operational needs.

MAC Automation

MAC Automation MAC Engineering

MAC Engineering