What is AI in Automation?

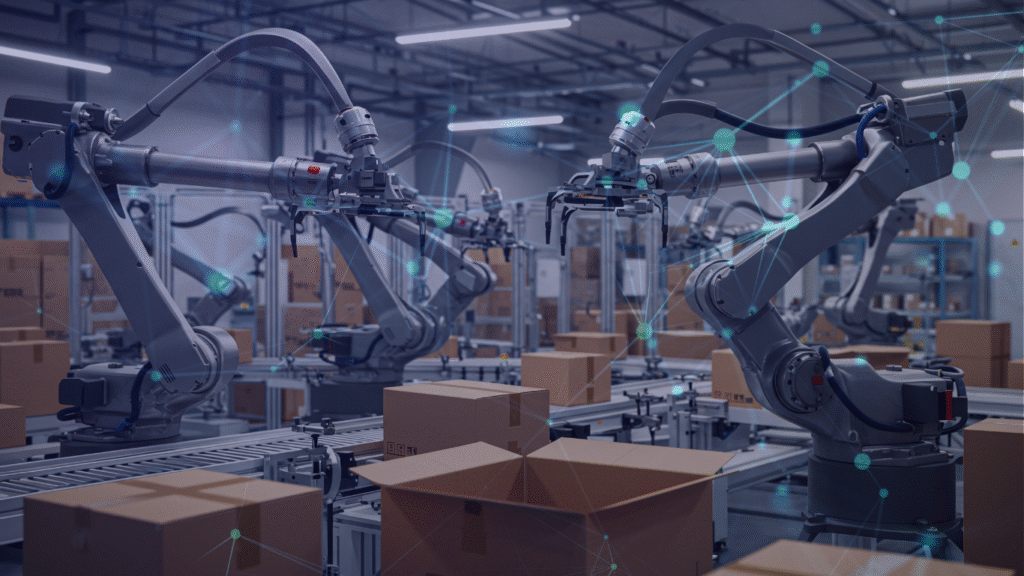

Artificial Intelligence (AI) in industrial automation is transforming how industries design, operate, and scale their processes. By allowing machines to learn, adapt, and make data-driven decisions, AI goes beyond traditional automation, which relies only on fixed programming.

In modern manufacturing and Industry 4.0 environments, AI in automation helps companies reduce defects, predict equipment failures, streamline production, and optimize supply chains. The result? Smarter factories, more reliable operations, and stronger competitiveness in global markets.

Why AI is Important in Manufacturing and Industrial Automation

Traditional automation executes the same task repeatedly, but it cannot adapt when conditions change. AI-enhanced automation adds intelligence to those tasks by analyzing data in real time and adjusting for optimal performance based on those data.

This means:

-

- Better quality control through AI-powered vision systems and predictive algorithms.

-

- Predictive maintenance that prevents costly downtime or even damage.

-

- Smarter production processes that reduce waste and cycle times.

-

- Data-driven insights that improve decision-making across operations.

-

- Collaboration between people and machines for safer, more efficient work.

From factory floor to customer’s door, companies are increasingly adopting AI in automation to cut costs, more quickly meet customer demands, and stay competitive.

5 Ways AI is Transforming the Automation Industry

1. Smarter Quality Assurance

AI vision systems detect even tiny defects at high speed, reducing scrap, rework, and customer returns. By improving inspection accuracy and consistency, manufacturers can deliver high-quality products more reliably and more quickly.

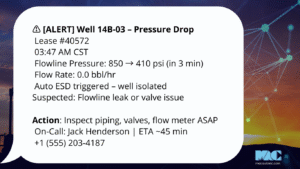

2. Predictive Maintenance

AI analyzes equipment and environmental data in real time to predict failures before they occur. This reduces unplanned downtime, extends machine life, and lowers maintenance costs. Predictive maintenance is one of the most widely adopted uses of AI in manufacturing.

3. Process Optimization

AI continuously adjusts production parameters to maximize efficiency and minimize errors. In industries like injection molding, casting, and electronics, AI-driven optimization means faster cycle times, less material waste, and higher output.

4. Supply Chain Intelligence

AI improves supply chain management by forecasting demand, optimizing logistics, and monitoring global operations. Smarter supply chains reduce costs, minimize delays, and keep manufacturers agile in volatile markets.

5. Human–Machine Collaboration

AI doesn’t just automate tasks but enhances them. Collaborative robots (cobots) and AI-assisted tools support workers, making jobs safer, faster, and more precise. This partnership increases productivity while improving workplace safety.

Outcome

AI in automation is now a competitive necessity. By bringing intelligence, adaptability, and predictive power to automation, AI enables industries to improve quality, reduce costs, and operate more efficiently.

For manufacturers embracing Industry 4.0, AI is the key to creating smart factories, optimizing production, and staying ahead in a rapidly changing world.

MAC Automation

MAC Automation MAC Engineering

MAC Engineering