Artificial Intelligence (AI) is reshaping how manufacturers monitor and control product quality. Traditional inspection methods depend on human oversight, which can lead to errors, slow inspections, and higher costs. AI-powered vision systems and predictive analytics deliver faster, more accurate, and more consistent results.

This article is part of our series on AI in Industrial Automation, exploring how artificial intelligence is transforming modern industry.

Why AI Matters in Quality Assurance

With real-time monitoring and adaptive analysis, AI makes quality assurance more efficient, scalable, and reliable. For manufacturers competing in the era of Industry 4.0, AI-driven quality assurance is becoming essential to reduce waste, improve throughput, and maintain customer trust.

Benefits of AI in Quality Assurance

Higher accuracy

AI vision systems detect even the smallest defects, achieving accuracy rates above 95% in industries like semiconductors and electronics (MDPI). By reducing errors and missed flaws, AI ensures fewer defective products reach customers which strengthens a company’s reputation for quality.

Faster inspections

AI-driven inspection tools can analyze thousands of parts per minute. In electronics manufacturing, AI has cut inspection cycle times by up to 40%, while aerospace manufacturers have reported efficiency gains close to 20% (Reuters). Faster inspections mean greater throughput and more consistent delivery schedules.

Lower costs

AI quality control reduces inspection costs by as much as 50% and lowers labor costs by more than 60% (FPT). Combined with fewer customer returns, these savings allow manufacturers to reinvest resources into growth and innovation.

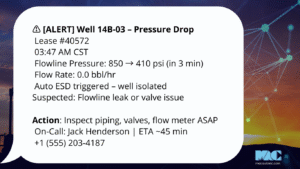

Predictive quality analytics

AI goes beyond defect detection. By analyzing production data, it can predict where quality issues may occur, enabling corrective action before defects spread across the production line.

End-to-end traceability

AI links inspection data directly to parts, batches, or production runs. This creates a digital record that simplifies compliance, makes recalls more efficient, and supports lifecycle quality management.

Real-time reporting

With AI, manufacturers can access live dashboards that track quality performance in real time. Managers gain immediate visibility into trends and can act quickly to keep standards high.

Outcome

AI in manufacturing quality assurance delivers measurable improvements in accuracy, efficiency, and cost savings. By combining defect detection, predictive analytics, and traceability, manufacturers gain more reliable production, lower risk, and stronger customer confidence.